.webp)

Metallurgical testing reveal microstructure, processes performed on the material during manufacture and whether or not the materials meet the required specification(s) to ensure durability in the intended use.

The following tests are available:

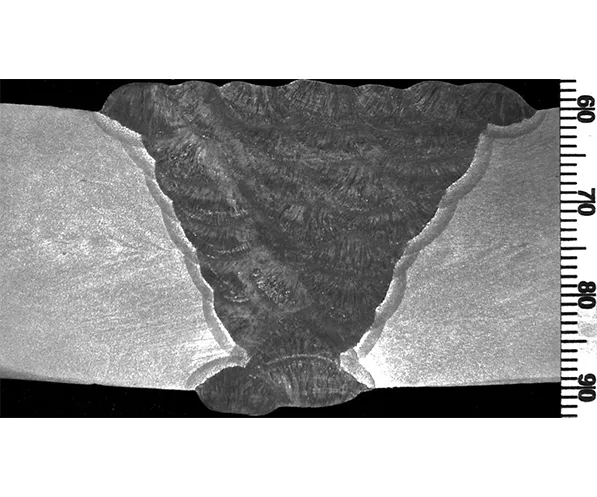

Macro examination involves the use visual methods and instrumentation to detect surface-level properties such as grain flow, porosity and cracks. For welds, characteristics such as weld size, fusion, penetration, profile, and weld discontinuities are examined.

Test Method / Specification is ASTM E340

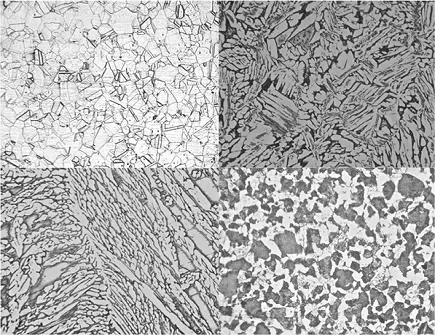

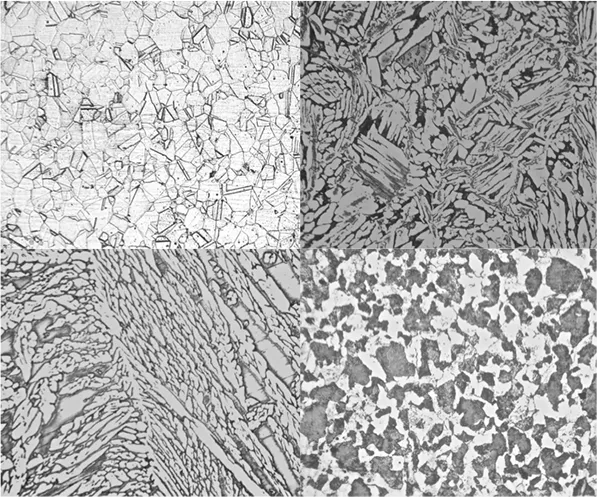

Metallographic examination uses microscopy to provide information about the structure and characteristics below the surface of metals. Samples are prepared using precision cutting, mounting, grinding, polishing techniques and etching. The findings are documented with photomicrographs.

Our metallography services include:

Corrosion testing is performed to assess the susceptibility of a metal to environmental attack and quantify its resistance to a corrosive environment.

Midwal Engineering performs the following corrosion tests: